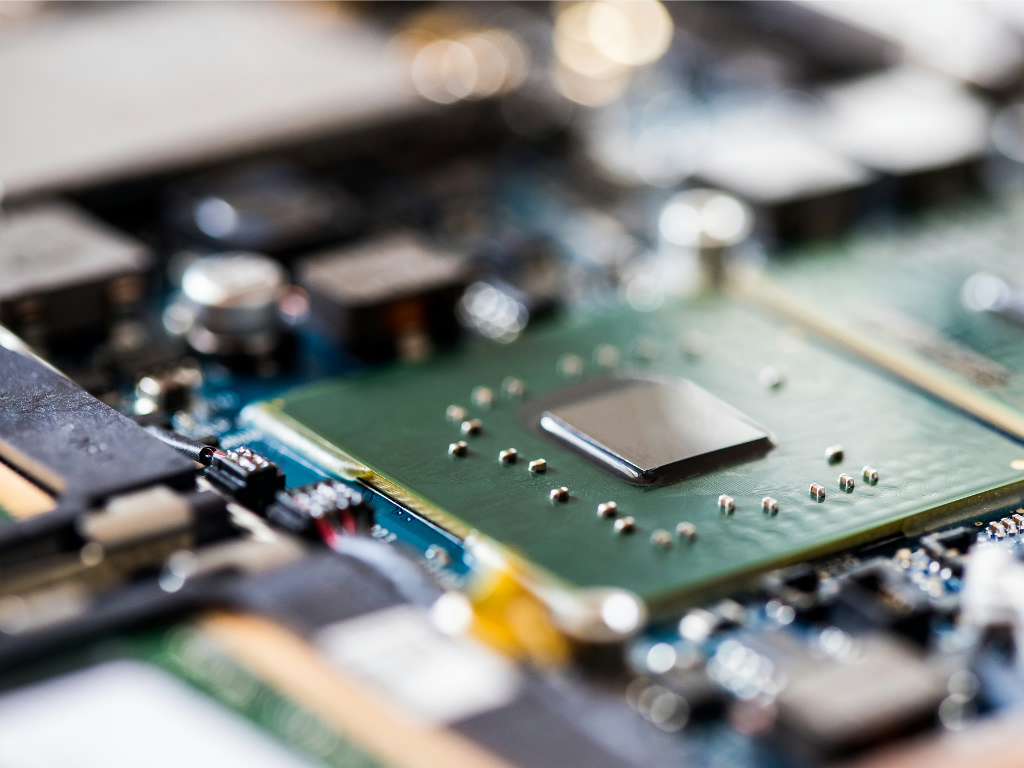

Most electronic products have the characteristics of being powered and having high unit prices. Therefore, the electronic components inside them need to maintain high sensitivity. Once in a humid environment, the internal electronic components will be corroded, resulting in various damage phenomena such as leakage and short circuit in electronic products, and customers will suffer huge economic losses.

Moisture problems:

Leakage and short circuit of electronic components;

Rust and corrosion of electronic instruments, reducing insulation strength;

Water stains and mold on the panel

Recommended solution:

Put a small package of desiccant in the package, or put the electronic products in a shielding bag

Recommended products:

Magnesium Chloride Desiccant, Silica Gel Desiccant, Montmorillonite Desiccant, Container Desiccant, Anti-static Shielding Bag

Application case:

Application of Montmorillonite desiccant: When electronic products are stored, electronic product manufacturers will add an appropriate amount of montmorillonite desiccant to each package to extend the service life of electronic products.

Application of Magnesium chloride desiccant: After automobile manufacturers produce some parts of the car, they will put an appropriate amount of magnesium chloride desiccant in the packaging process to easily prevent the damage of automobile parts due to moisture.

Application of container desiccant: In order to avoid damage to electronic products caused by "container rain" during sea transportation, a proper amount of desiccant sticks can be hung inside the container of electronic products to prevent condensation from dripping on the cartons and causing damage to electronic products.

Application of Anti-static Shielding Bag: During the production and packaging of electronic parts, electronic parts manufacturers can put the parts into shielding bags and seal them to ensure that the electronic parts are in a dry environment during storage or transportation.