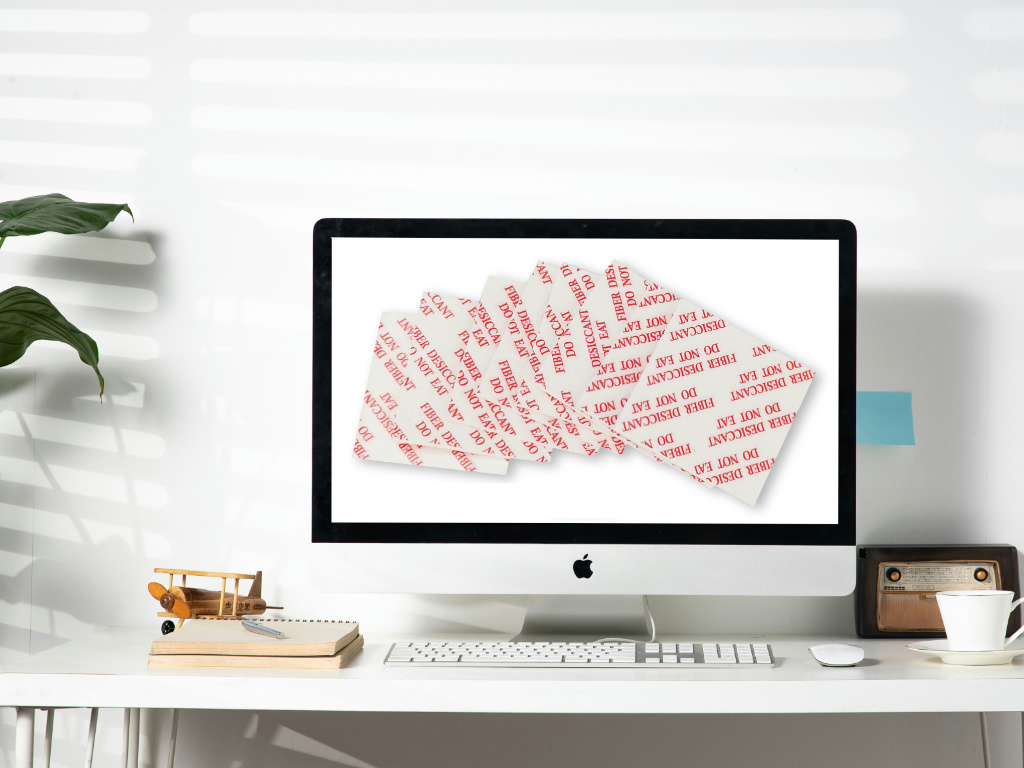

Huawin filmed fiber desiccant, PET film, is in the form of a paper sheet, which can be cut into different shapes freely, and can fit various products well. It can be used in ordinary packaging structures, making it a functional packaging. It is an ideal choice for many electronics, shoes and clothing products.

Product Features :

Mildew-proof and moisture-proof, plant fiber, individual judgment, non-corrosiveProduct Ingredients :

plant fiberProduct specifications :

can be customized (consult customer service)Processing method :

OEM/ODMProduct Origin :

Fujian,ChinaProduct Introduction

Huawin Filmed fiber desiccant desiccant is made of plant fiber as a carrier, and is refined through soaking, drying, film covering, cutting and other processes. It is convenient and practical, with strong hygroscopicity and a moisture absorption rate of up to 100%. And it can be cut or punched into various shapes and sizes, empowering ordinary packaging structures, making it a functional packaging, which is an ideal choice for many electronics, shoes and clothing products.

Product Parameter

|

Product name |

Filmed fiber desiccant |

|

Product brand |

HUAWIN |

|

product raw material |

plant fiber |

|

product appearance |

coated paper sheet |

|

Product size |

can be customized (consult customer service) |

|

Shelf life |

18 months under sealed storage |

|

Scope of application |

Widely used in electronic materials, leather products, shoes, clothing, bags, handicrafts, garments, cultural relics, etc. |

Product Demand

Do you know the dangers of humidity?

During product packaging or storage and transportation, water vapor in the air will invisibly infiltrate into the product, thus suffering from product discoloration, deformation, odor, mildew, corrosion and other moisture damage.

Application Scenario

These scenarios require the use of filmed fiber desiccant desiccants

Widely used in electronic components, precision instruments, electronic components, bottled medicines, biological reagents, clothing, shoes and hats, leather products, handicrafts, musical instruments, cultural relics and other fields.

Case presentation

Since the fiber desiccant can be freely cut into different shapes, it can fit various products better and realize moisture-proof "stealth"

Product Description

Fiber desiccant before and after hygroscopic comparison

Huawin laboratory test results show that under the conditions of temperature: 25°C and humidity: 90%, the medicine without fiber desiccant becomes moldy and discolored, while the medicine with fiber desiccant is intact, and no mold growth is seen on the surface.

Technical Requirement

Technical Requirements of Fiber Sheet

|

Moisture Absorption Rate 25℃ RH20% RH50% RH80% |

Thickness |

Water Content Rate |

Appearance |

|||

|

Fiber Sheet |

≧10% |

≧30% |

≧70% |

1mm |

≦5% |

The surface is clean and tidy The printing is clear |

Product Features

1.Choose materials carefully, use them with confidence

Selected plant fibers are used as raw materials. After testing, they are tasteless, non-corrosive, degradable, renewable, and chemically stable, so you can use them with peace of mind.

2.High moisture absorption rate, outstanding performance

The fiber desiccant has a strong hygroscopic ability, the moisture absorption rate is as high as 100%, and compared with the traditional silica gel desiccant, the hygroscopic performance is more outstanding, and the fiber sheet changes from hard to soft after moisture absorption.

3.Small and light, personalized customization

The thickness is only 1mm, and the shape is slim and does not occupy much space. It can be personalized or punched into various shapes and sizes, and it is convenient to use.

4.PET film, pattern customization

The shape is like a piece of paper, and the upper and lower sides are covered with colored PET film, which is not only beautiful but also meets the needs of customized printed text.

Product Customization

All of our desiccant products can be customized, consult customer service to choose desiccant products suitable for you!

Consultation and negotiation → determination of cooperation intention → determination of raw materials and packaging materials → determination of sample design → proofing and sending → signing of contract → mass production → shipment

Notes

Notes In Storage And Use Of Desiccant

1、Storage: the desiccant must be sealed and stored in a cool, dry and chemical-free warehouse, isolated from the outside air, so that the next use will not be affected.

2、Transport: desiccant should be handled carefully in the process of transportation to avoid abrasion of internal and external packaging, at the same time to prevent contact with acid and alkali substances, to avoid sunlight and rain and snow, fire prevention, moisture-proof.

3、Use:

①The desiccant needs to be used in a dry environment.

②Check whether the sealing of the packaging container is good before use, and the vacuum packaging products need to check whether the vacuum bag packaging container is damaged. If there are instructions for silica gel products, indicate whether the silica gel is discolored before use. Ensure that only under the above conditions can you use it.

③Desiccant should be used as soon as possible after opening the packaging container. According to the actual factory usage, unused desiccant should be sealed and stored in time.

④When using the desiccant, the desiccant bag should not be squeezed and rubbed, and the desiccant bag should not be thrown at will, so as to avoid damage and leakage of the desiccant bag.

Tags :